Innovative automation solutions for the future – Efficiency and precision for your industry

Experience how B&R takes your production processes to the next level with the latest technology, seamless integration and maximum flexibility in our Innovation Spotlight.

AI-enhanced pick-and-place

Deep learning object detection makes it possible to detect shapes—even when edges are unclear, backgrounds are noisy, or edges overlap. This simplifies robot-machine interaction for more flexible and reliable pick-and-place, inspection and handling applications. Intuitive setup and configuration require minimal expertise in vision and AI. Discover more

AI-enhanced pick-and-place

Deep learning object detection makes it possible to detect shapes—even when edges are unclear, backgrounds are noisy, or edges overlap. This simplifies robot-machine interaction for more flexible and reliable pick-and-place, inspection and handling applications. Intuitive setup and configuration require minimal expertise in vision and AI. Discover more

Plug-and-play SCARA

SCARA robots offer speed and precision in a compact footprint, with easy mounting for pick-and-place, loading/unloading, assembly and dispensing applications - even in cleanrooms. Like all Codian models, they are available as open hardware or a complete Machine-Centric Robotics solution with synchronized control, fast commissioning, and unified engineering - no robotics expertise needed. Discover more

Plug-and-play SCARA

SCARA robots offer speed and precision in a compact footprint, with easy mounting for pick-and-place, loading/unloading, assembly and dispensing applications - even in cleanrooms. Like all Codian models, they are available as open hardware or a complete Machine-Centric Robotics solution with synchronized control, fast commissioning, and unified engineering - no robotics expertise needed. Discover more

Adaptive safety for the smart factory

With Safety+ B&R introduces an open approach to safety programming, compatible with tools like GitHub and Jenkins for agile development. An open data architecture and digital fingerprinting support flexible programming languages and data types, making safety applications as productive as standard automation. With traceable changes down to individual functions, Safety+ empowers engineers to innovate safety solutions quickly – without compromising control. Discover more

Adaptive safety for the smart factory

With Safety+ B&R introduces an open approach to safety programming, compatible with tools like GitHub and Jenkins for agile development. An open data architecture and digital fingerprinting support flexible programming languages and data types, making safety applications as productive as standard automation. With traceable changes down to individual functions, Safety+ empowers engineers to innovate safety solutions quickly – without compromising control. Discover more

New automation engineering experience

Automation Studio Code offers engineering teams a whole new way to interact with their projects and each other. A modern, intuitive interface and advanced engineering features make work easier than ever. DevOps integration ensures smooth, efficient and reliable software delivery pipelines. With an AI-powered expert coding assistant and the flexibility of cloud-based collaboration, developers can do their best work and deliver smarter solutions faster. Discover more

New automation engineering experience

Automation Studio Code offers engineering teams a whole new way to interact with their projects and each other. A modern, intuitive interface and advanced engineering features make work easier than ever. DevOps integration ensures smooth, efficient and reliable software delivery pipelines. With an AI-powered expert coding assistant and the flexibility of cloud-based collaboration, developers can do their best work and deliver smarter solutions faster. Discover more

Don't miss an innovation

Subscribe to the Spotlight newsletter for exclusive insights into the future of automation.

Stay up to date!

Welcome to our innovation showcase

Where our latest breakthroughs and big ideas take center stage. Where we discover what happens when a passion for pushing limits meets a hunger for sustainable productivity in a world of constant change.

Starting November 12, 2024, we will be bringing you regular updates with new groundbreaking innovations. We invite you to join us on this journey and be the first to hear about each new arrival in the arena of open, intelligent machine automation.

Our innovative solutions

- Software

- PLC & I/O systems

- Industrial PCs

- HMI

- Motion control

- Vision systems

- Mechatronic systems

- Robotics

Centralized access for streamlined operation

mapp Cockpit is now the single point of entry for all support and diagnostics—that means faster troubleshooting and more efficient workflows. Starting with Version 6.3, mapp Cockpit provides intuitive access and seamless navigation for all online help and system diagnostics pages, including controls and motion as well as safety and vision.

No-code commissioning

mapp Cockpit 6.3 enhances usability with a graphical interface and no-code commissioning. The new mapp Motion axis pages greatly simplify commissioning steps. By providing self-explanatory guided workflows and intuitive tools, it minimizes setup complexity and improves machine uptime with faster issue resolution.

AI-assisted programming

Automation Studio Copilot integrates generative AI into automation programming, translating ideas in natural language straight into executable machine code. It can also annotate, optimize and summarize complex code for easier collaboration. Integrated in the new Automation Studio Code environment for easy use, Copilot enhances efficiency and helps developers achieve high-quality results with less time and effort.

Real-time insights for planar product transport

The ACOPOS 6D Diagnostics Widget is the perfect companion for B&R's planar product transport solution. Designed to reduce downtime and enhance system reliability, it simplifies system monitoring and troubleshooting by providing intuitive diagnostics and clear troubleshooting information right on the HMI screen or tablet. Ideal for both developers and operators, it enables real-time monitoring, fast error correction, and seamless data sharing with support teams.

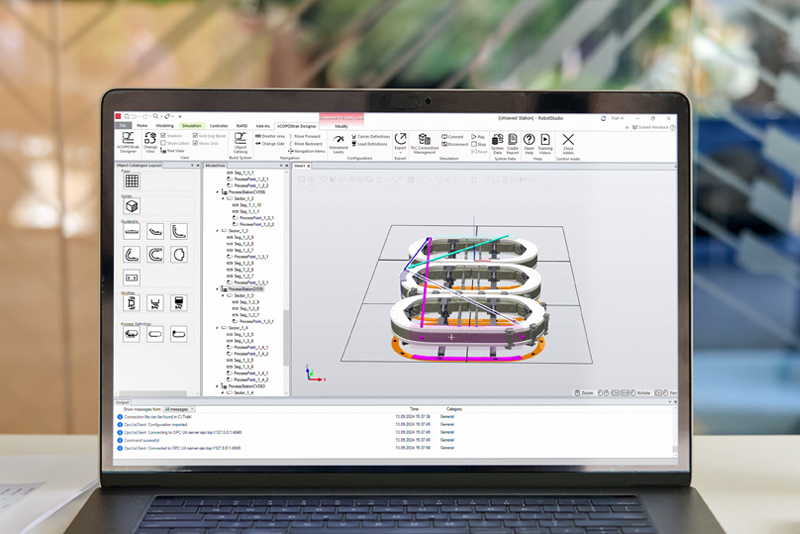

3D no-code track design

ACOPOStrak Designer makes complex track layouts easy with 3D configuration, real-time feasibility analysis, and zero programming. Visualize customer needs in seconds and fine-tune parameters during meetings, reducing development time. The digital twin simulates real-world dynamics for optimal performance, while direct export to Automation Studio speeds up setup and commissioning.

Flexible collaboration with selective versioning

The latest version of Automation Studio introduces Selective Versioning. This feature decouples project versions from the software version, allowing teams maximum flexibility without compatibility issues or conversions. Machine builders can easily maintain multiple projects across large teams. Engineers can selectively apply updates to specific sub-components like Automation Runtime or mapp Technology, accelerating development and reducing testing time for faster, more flexible project management.

The key to data-driven optimization

The IIoT Connector app simplifies data sharing between machines and IT systems, turning raw machine data into actionable insights. With seamless support for B&R-specific and standard IT interfaces (like MQTT, cloud, and databases), it enables solutions for tuning equipment performance, optimizing energy use, and extending asset life. Plus, users can freely choose which data to share with ERP, SCADA, and IoT systems.

Performance tuning, energy optimization and more

ACOPOStrak Monitor provides real-time monitoring, predictive maintenance, and lifecycle insights for linear transport systems. Like a fitness tracker for machines, it detects misalignment and wear issues early, reducing total cost of ownership. With cloud connectivity and easy diagnostics, this monitoring tool aids in proactive maintenance and streamlines machine performance for maximum uptime without the need for an external sensor.

Cloud-based collaborative engineering

Explore a cloud-based collaborative environment designed to streamline automation projects directly from your browser. It breaks down development silos, enabling seamless cloud collaboration across distributed teams and provides a unified project overview. Key features include easy integration with your repositories as GitHub, a clear view of the codebase, and the ability to launch development environments with a single click – dependencies and versions are pre-set for immediate coding. Share projects securely with colleagues, partners, or clients, enhancing collaboration while maintaining strict access control.

Smarter and more secure grids

B&R advances substation automation and smart grid operations with the integration of DNP3 and IEC 61850. These standards help simplify engineering, reduce downtime, and deliver more secure, flexible, and future-ready grid operations by enabling real-time monitoring, secure data acquisition, and standardized system configuration. IEC 61850 delivers high-speed, event-driven communication and standardized data modeling for efficient control, while DNP3 ensures reliable performance over challenging networks. Speak with our expert to learn more.

Open and secure, time-critical communications

OPC UA FX C2C (Controller-to-Controller) technology enables precise, secure, and time-critical data exchange between machines, ensuring optimal performance in demanding environments. Engineered for high-performance tasks with low, guaranteed latency, it is ideally suited for applications such as robotics and motion control. With its open, standardized design, OPC UA FX C2C fosters interoperability across diverse systems, supporting various Quality-of-Service (QoS) levels on shared networks. Combined with robust end-to-end security, it empowers manufacturers to build scalable, interoperable networks – driving efficiency and advancing the smart factories of the future.

Uninterrupted engineering

Automatic login means fewer interruptions for engineers when commissioning and testing machine applications in simulated environments. Once development is complete, security protocols ensure proper authentication for production. By balancing security and usability, this update in mapp Cockpit 6.3 simplifies access while maintaining strict control over machine data.

APC3200 mobile ISOBUS certification

APC3200 mobile is the first industrial PC certified for ISOBUS, simplifying integration in modern agricultural equipment. With ready-to-use compatibility, it removes the need for custom ISOBUS stacks and reduces development time. OEMs can focus on machine functionality while ensuring seamless communication with ISOBUS systems. This solution enhances efficiency, compatibility, and long-term value.

Compact motor control

B&R’s new ACOPOS X2 drives bring versatile motor control for cost-sensitive applications, allowing machine builders to control stepper and brushless DC (BLDC) motors up to 1kW. With 48V low-voltage technology, these compact drives offer two axes per device in a slim 27.5 mm footprint, freeing up cabinet space. Fully integrated into the X20 portfolio, they include onboard SIL3 STO safety and support various encoder types or encoder-free applications, making setup adaptable and streamlined. This integration delivers enhanced performance and easy customization across printing, packaging, and material handling applications.

Connected IT-OT intelligence

B&R's X20 Edge connects machine control with enterprise systems for enhanced production insight. Equipped with an ARM-based CPU and Linux OS, it provides flexible programming possibilities like Python and a containerized environment for deploying AI, machine learning and IIoT applications. Dual Ethernet ports open up communication possibilities like OPC UA and cloud connectivity, creating a seamless data flow between machines and IT infrastructure. Ideal as a smart IIoT gateway, the X20 Edge offers machine builders simplified integration of digital services, while end users gain access to advanced analytics – all in a compact, industrial-grade device.

Effortless signal management

B&R's high-density I/O modules help machine builders simplify processes, optimize costs, save space and reach new levels of flexibility and efficiency. High-density module variants offer multifunctional I/O, advanced signal processing, and seamless integration of IO-Link and sensor technologies - with up to 32 configurable channels in a width of just 27.5 mm.

Next-gen maritime controller

X90CP150 is DNV-certified and supports SIL 3 safety in a compact, cabinet-free design. Ideal for maritime and offshore environments, it enables integrated control and safety without external systems. Machine builders benefit from reduced engineering and component count, while end users gain simplified maintenance and high operational reliability in critical applications.

Future-proof PC performance

B&R's 2300-series PCs feature Amston Lake Atom processors and high-speed connectivity with 2.5 Gbit Ethernet ports. The 3200-series balances high performance with low maintenance with a fanless design based on a 13th gen core i CPU. Both series operate on CFexpress mass storage to serve ultra-fast data rates and meet the demands of continuous operation in compact form and feature flexible real-time OS options, pre-activated Windows 10 IoT, Linux for B&R 12, and Windows 11 IoT, and rigorous product testing operations for long-term system reliability.

Unlock smarter web HMI

The new Terminal OS unlocks more powerful web and VNC client capabilities for B&R’s Panel PCs. Designed for high-performance visualization, it ensures smoother operation of demanding applications while simplifying system architecture. Use it as a standalone OS or in a hypervisor-based setup to scale performance without major hardware changes.

Maritime-certified PC

DNV and CCS certification for the Automation PC 4100 confirms compliance with maritime and offshore safety standards, ensuring reliable operation in harsh environments. B&R’s high-end industrial PC series minimizes failure rates and service requirements, making it a trusted choice for demanding applications – from the plant floor to the high seas.

JavaScript for dynamic HMIs

mapp View 6.3 introduces native JavaScript support, enabling developers to build responsive, high-performance HMIs using familiar web development tools. By leveraging existing JavaScript skills and libraries, machine builders can accelerate development, create custom widgets, and make smoother animations. The results are smoother animations, faster screen transitions, and highly tailored user experiences that meet modern expectations in industrial automation.

Unlock smarter web HMI

The new Terminal OS unlocks more powerful web and VNC client capabilities for B&R’s Panel PCs. Designed for high-performance visualization, it ensures smoother operation of demanding applications while simplifying system architecture. Use it as a standalone OS or in a hypervisor-based setup to scale performance without major hardware changes.

DNV-certified HMI

T50 mobile operator terminals are now DNV-certified for reliable operation in maritime and off-highway environments under extreme conditions. Built on the same platform as cabinet-mounted models, they enable seamless engineering and project management across applications. Their rugged design supports faster deployment, reduced maintenance, and a consistent user experience across all equipment types.

Adaptive vibration bowl control

Set it, tune it, run it: plug-and-play vibration bowl control on ACOPOS P3 servo drives adapts parameters to changing conditions in real time, optimizing energy efficiency in each process cycle. Advanced diagnostics and predictive insights help reduce mechanical wear, increase energy efficiency and improve sorting accuracy.

Decentralized IP55 control

ACOPOSinverter P96 simplifies machine design with its rugged IP55 case, enabling cabinet-free installation. Supporting power classes up to 250 kW, it enhances heat dissipation, reduces wiring complexity, and improves reliability. With ready-made function blocks and daisy-chain STO, it streamlines commissioning and boosts safety.

Intelligent drives, instant decisions

Meet the next generation of intelligent drives: AI-powered ACOPOS drives integrate intelligence directly at the device level, enabling real-time detection and response to mechanical changes—without cloud dependency or external sensors. By processing data locally, they optimize network usage, reduce controller load, and improve energy efficiency. The result? Simplified setup for machine builders and enhanced reliability, lower maintenance, and consistent performance for end users.

Power Packed in Elegance: Slim, Smart, Effortless

ACOPOSInverter P77 makes automating equipment like fans, pumps, and conveyors simple and efficient. At 60x130 mm, it features one of the slimmest designs on the market. Fully integrated with B&R’s software toolchain, it enables faster software design with mappMotion, simplifies commissioning with mappCockpit, and supports flexible lifecycle management with hardware-independent software.

More power, smaller footprint

B&R’s 8LSA-4 motors pack more power into a compact design, featuring a market-leading power-to-volume ratio. This allows machines to achieve equal or greater output in a smaller footprint, reducing mechanical components and boosting energy efficiency. Ideal for applications requiring high efficiency and space savings, the 8LSA-4 motors help machine builders streamline designs while lowering energy costs.

Performance and safety redefined

ACOPOS P87 inverters deliver precise motion control with advanced features like network-based safety using openSAFETY over POWERLINK as well as a hardwired dual channel safe torque off input (STO). Designed for hoisting, positioning, and advanced safety applications (SLS, SS1), it combines premium capabilities with seamless integration into B&R’s software ecosystem, ensuring reliability across diverse industries.

Powerful servo for harsh environments

A power extension to the ACOPOS P3 servo drive family delivers double the power density and up to 80 kW, ideal for high-demand industries like plastics, paper, metals, and textiles. With a 60% smaller cabinet footprint, these robust, dustproof drives simplify layouts and reduce maintenance. Accurate fan control, adaptive PWM switching frequency, and an intelligent notch filter for vibration suppression boost reliability and extend lifespan. The new ACOPOS P3 provides high performance for both single and double axes with 50 µs cycle times.

Encoder accuracy for digital manufacturing

B&R motors and ACOPOS P3 servo drives now support the EnDat 3 protocol, providing high-resolution positioning and maintenance data, like motor temperature and status. EnDat 3’s 2-wire connection reduces cable weight and bending radius, enabling compact machine designs. Daisy-chaining through the motor encoder allows dual encoders with less cabling and a smaller footprint.

Smarter, simpler motion control

ACOPOS P3 now supports the EnDat 3 digital encoder interface, cutting cabling from six wires to two – improving flexibility and enabling smaller cable carriers. Daisy-chaining simplifies wiring, reducing installation complexity and cost. Advanced diagnostics provide real-time insights into encoder temperature, vibration, and signal anomalies for predictive maintenance. Existing systems can upgrade to EnDat 3 via a firmware update – no hardware changes required.

Fast engineering, fast execution

The newly enhanced SPT Editor offers an intuitive and efficient solution for writing, configuration, and debugging of B&R's ultra-fast 50-µs motion control function blocks. Designed to streamline development workflows, it significantly reduces engineering effort while ensuring maximum precision and performance. With this advancement, Smart Process Technology (SPT) is now more intelligent and user-friendly than ever.

Flexible motion with DS402 support

B&R’s mapp Motion now supports the DS402 standard drive profile, enabling seamless integration of third-party servo drives across multiple fieldbuses. OEMs gain greater flexibility in machine design and sourcing, with simplified configuration and reusable applications that speed up development. The result is faster time-to-market, lower engineering effort, and future-proof motion systems that can easily adapt to evolving requirements and component availability.

One drive for all power sources

B&R’s ACOPOS P3 servo drive sets a new standard for flexibility for AGVs and mobile machines by seamlessly supporting both AC and DC power in a single compact unit. Its broad DC range of 24–120 Vallows effortless transitions between battery-powered mobility and AC-powered docking—without requiring hardware changes. Integrated SafeMotion functions ensure safety across all operating modes, while CE/UL certification simplifies compliance. Designed for the future, it also supports renewable energy sources, enabling compact, energy-efficient, and versatile designs.

Flexible flash integration

For machine builders looking to integrate third-party lighting into their automation setup, B&R’s new flash controller offers a flexible solution. It allows any current-driven lighting system to be used just as seamlessly as an integrated B&R Smart Light. It ensures precise synchronization with µs accuracy, even with external lighting, thanks to its single-wire connection and rapid flash current rise times. Machine builders benefit from lower cabling costs, reduced cabinet space, and an open approach, while end users enjoy higher quality and productivity with consistent performance.

AI smart camera for real-time automation

The B&R smart camera perfectly synchronizes AI image processing with real-time data, keeping vision in the control loop for maximum precision. A specialized AI processor provides fast and accurate deep learning functions including anomaly detection and optical character recognition (OCR). An intelligent combination of rule-based and AI-driven tools ensures precise defect detection and enables machine builders to tackle complex vision challenges faster. Integrated asset management functionality and a deep learning tool for training and evaluation keep productivity high and costs low.

3D vision tasks: Cost-optimized

A clever extension for B&R smart sensors and cameras uses laser triangulation with FPGA preprocessing to deliver a cost-optimized solution for solving 3D tasks in mid-range applications. B&R's 2.5D vision solution captures moving objects to enable height monitoring, sorting, volume estimation and more. Machine builders can simplify system complexity with an integrated system – e.g. no need for a transducer. Vision can be synchronized to highly dynamic movements with nanosecond precision. End users benefit from easy operation, higher OEE, and reduced energy consumption and hardware footprint – all with the precision of advanced 2D algorithms.

"What is it?"

By answering this question, AI-based classification enables B&R Smart Cameras to recognize and sort images. Similar to how humans distinguish cats from dogs, regardless of breed, deep learning analyzes shape, texture, and more to accurately differentiate between products and variants. B&R's deep learning toolchain streamlines setup with predefined training parameters. By eliminating complex manual configuration, it reduces errors, simplifies adaptation to new data, and ensures flexible, efficient production.

Same footprint, twice as productive

Tight curves are crucial in a compact line design. The ACOPOStrak 180° compact curve delivers high-density production with a slim 330 mm width and can be used in any orientation – including space-saving vertical mounting. Enabling two units in the space of one, it doubles productivity and helps make ACOPOStrak one of the world’s most compact track systems. IP69K-rated for easy washdown and with optional advanced cooling, this track segment suits the high demands of food and beverages, pharmaceuticals and more.

More flexible layout in planar transport

from 160x160 mm for maximum design density to 600x600 mm for maximum payload capacity. The existing family of 240x240 segments is joined by a new 480x120 mm rectangular segment. Washdown hardware options for aseptic and hygienic applications let ACOPOS 6D streamline operations across diverse industries.

Cost-efficient expansion

The new 120x480 mm segment enables more cost-effective ACOPOS 6D layouts, reducing the number of segments needed per system. Designed for single-lane transport or as a third lane alongside 240x240 mm segments, it provides an efficient solution for handling larger shuttles and optimizing space usage in compact production lines.

Cool under pressure

New liquid cooling for SuperTrak ensures reliable 24/7 operation by effectively dissipating heat, even under demanding production conditions. Designed to support high-traffic segments and multi-pallet processing. Mounting directly to track segments, this cooling solution enhances uptime, lowers energy costs, and extends system lifespan for continuous, efficient operation.

Track and conveyor hand-in-hand

ACOPOStrak Hybrid integrates intelligent and conventional transport with seamless transfer of products between tracks and conveyors. Ready-to-use software for automatic handover reduces development time. From intralogistics solutions with long transport distances to high-speed filling lines, ACOPOStrak Hybrid maximizes 3D space utilization and makes adaptive solutions economical in any situation.

Advanced project support

B&R’s Mechatronic Services combine dedicated project teams with direct access to R&D labs, helping machine builders optimize systems from concept to implementation. Engineers, product experts, and R&D specialists work with customers to validate designs, test real products, and fine-tune performance. The result: reduced risk, faster time to market, and reliable, high-performing machines tailored to exact application needs. Services span ACOPOS 6D; ACOPOStrak, SuperTrak and robotics, with both remote and on-site support options for maximum flexibility.

Drag-and-drop expert tuning

Effortless deployment of custom robotic mechanics - no manual sync work or extra software needed. The B&R Mechatronics Services team handles ISO 9283-based tuning and delivers the result as a ready-to-use Automation Studio add-on. Just drop the pre-tuned mechanics into your project - and you're good to go.

The efficient pick

Codian Greenline (D4-ST21) delta mechanics are the best choice for high-speed, lightweight pick-and-place applications like those frequently found in the packaging sector. The compact design enables tighter nesting of robots to save space and meet ever increasing needs for more compact machine layout. Not only is this performance upgrade to the popular S020-series more ecologically friendly in terms of materials used and footprint reduction – it simultaneously delivers increased stiffness for uncompromised precision and quality.

Up to 30% more throughput

B&R's pick-and-place solution enables synchronized, collision-free robotic operations in overlapping work zones, increasing throughput by up to 30% and enabling higher density line design. Dynamic payload-based adjustments ensure maximum performance, reduce wastage, and together with multi-gripper support enable the complex handling sequences needed to maximize efficiency. Developers are supported by real-time visualization of how the robot, products and transport system will interact.

Robotics goes multicore

With Automation Studio 6 and mapp Technology 6, machine builders can now run up to three times more robots on a single Automation PC. This multicore capability allows more efficient use of computational power, freeing up capacity for complex applications or non-real-time tasks – all without the need for advanced multi-threading programming. The result is higher performance, reduced programming complexity, and a smaller cabinet footprint, making robotics control more powerful and cost-effective.